Loading Unit LK Armatur 810

• Automatic loading unit for solid-fuel/storage tank installations

• Makes the boiler reach an optimum operation mode faster which means less environmental impact

• Ensures a constant minimum return temperature into the boiler which increases boiler efficiency, prevents tarring and considerably

prolongs the lifetime of the boiler.

• To ensure a maximum supply of hot water from boiler to storage tank an automatic balancing valve closes the by-pass loop in the end phase of the firing time.

• LK 810 is for boilers with a capacity up to 90 kW.

Loading Unit LK 810 is an automatic loading unit for solid-fuel boiler/storage tank installations. The loading unit ensures a minimum return-water temperature into the solid fuel boiler, which increases boiler efficiency, prevents tarring and considerably prolongs the life-

time of the heating boiler.

Loading Unit LK 810 eliminates the risk of destructive thermal shock caused by surges of cold return water and renders a more effective burning. The heating boiler quickly reaches the right working temperature. In the end phase of the firing an automatic balancing valve

closes the by-pass loop. This results in a maximum cooling of the boiler and the storage tank is fully filled with hot water.

Loading Unit LK 810 comes in two versions, with or without backflow preventer.

With the backflow preventer the LK 810 automatically allows self-circulation as soon as the fire has gone out so that the rest of the heat in the boiler is transferred into the storage tank. It also allows self-circulation in case of power failure.

Loading Unit LK 810 operation and maintenance

Loading Unit LK 810 normally requires no maintenance. The loading unit has three ball valves.

Any part can be changed without draining the system.

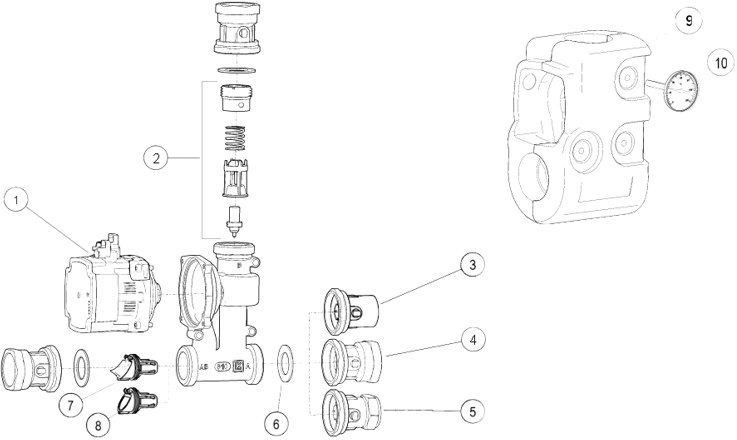

Loading Unit LK 810 main parts

1. Thermally operated loading valve

2. Automatic balancing valve

3. Backflow preventer, depending on model

4. Circulation pump

5. Three thermometers

6. Three ball valves

7. Insulation EPP

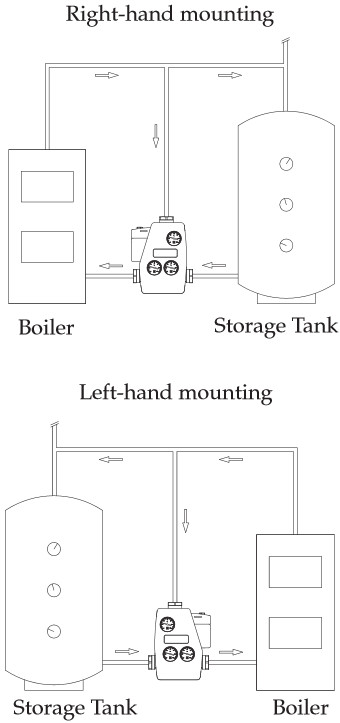

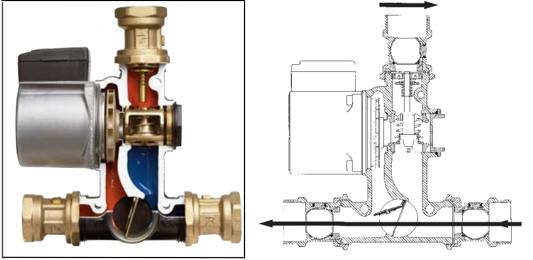

Loading Unit LK 810 mounting / installation

The valve unit is mounted upright either on the right or left hand side of the boiler. The thermometers are pressed onto the front side of the unit.

For a trouble free system the piping work must be done without air pockets. If this is not possible the system must be fitted with air vents.

Several boilers have integrated thermostats for pump control. If not, a flue gas thermostat must be installed. The circulation pump should start at the same time as the firing.

The pump should stop soon after the fire has gone out to let the remaining hot water in the boiler self-circulate to the storage tank.

Loading Unit LK 810 dimensioning

Pipe dimensioning between heating boiler and storage tank:

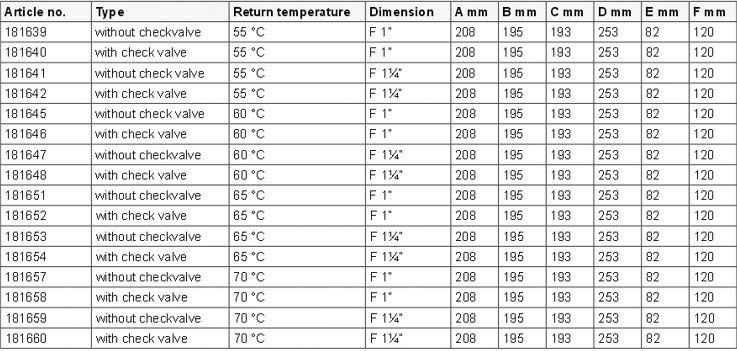

- LK 810 ThermoMat 2.0 G loading unit with Rp 1” ball valves. For heating boilers up to 40 kW ..... DN 25

- LK 810 ThermoMat 2.0 G loading unit with 28 mm ball valves. For heating boilers up to 40 kW .... CU 28

- LK 810 ThermoMat 2.0 G loading unit with Rp 1¼“ ball valves. For heating boilers up to 65 kW .... DN 32

Loading Unit LK 810 function of the backflow preventer

The LK 810 loading unit has, depending on model, a backflow preventer which automatically opens for selfcirculation when the pump stops. The backflow preventer has the following functions:

1. After the fire has gone out and the circulating pump has stopped the remaining hot water will selfcirculate to the storage tank.

2. In case of power failure the hot water will self-circulate to the tank.

3. It prevents backfl ow from storage tank to heating boiler.

The function of the backflow preventer can, if needed, be blocked.

Loading Unit LK 810 function

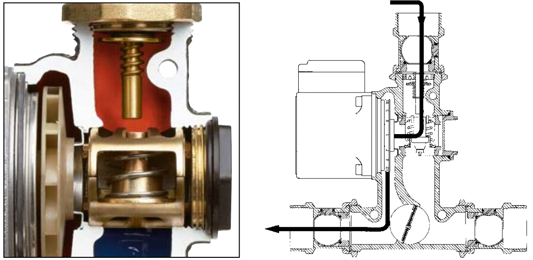

1. Heating phase

The boiler water circulates to the loading unit and back while the temperature of the boiler is rising.

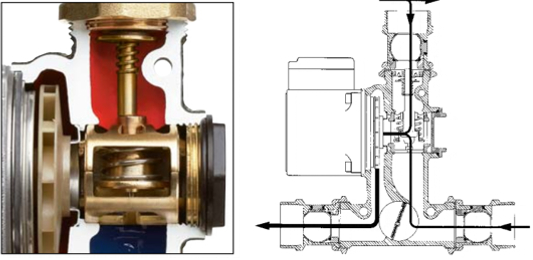

2. Loading phase

The thermostatic element starts to open and allows return water from the storage tank to be mixed with supply water before it returns back to the boiler. The return temperature to the boiler is constant.

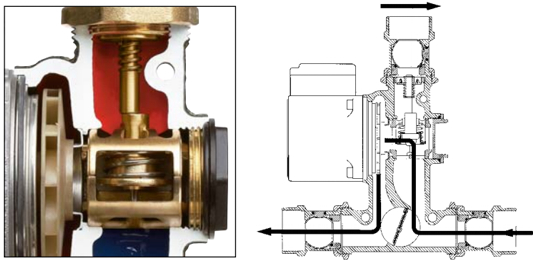

3. End phase

The thermostatic element is fully open. The balancing valve is closed. This results in a maximum cooling of the heating boiler and the storage tank is fully filled with supply water.

4. Self-circulation with a backflow preventer

Self-circulation is obtained as soon as the fire and the circulating pump have stopped. The remaining hot water self-circulates to the storage tank.

In case of power or pump failure the backflow preventer automatically opens for self-circulation.

The backflow preventer stops the self-circulation from tank to boiler.

1. 187168 Pump head Grundfos UPM3 Auto L

2. 187163 LK 810 Thermostatic element 55°C

2. 187164 LK 810 Thermostatic element 60°C

2. 187165 LK 810 Thermostatic element 65°C

2. 187166 LK 810 Thermostatic element 70°C

3. 187017 Ball valve Rp 25

4. 187018 Ball valve Rp 32

5. 187019 Ball valve 28 mm

6. 013057 EPDM 44x32x2 mm

7. 187021 Backflow preventer

8. 187022 Plug

9. 187167 EPP Insulation

10. 180352 hermometer 0-120°C

LK 810 Thermomat with check valve:

LK 810 Thermomat without check valve