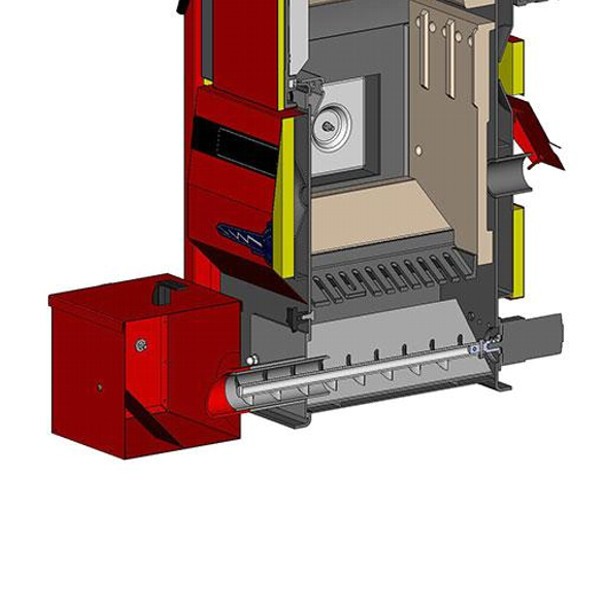

This automatic device uses a worm conveyor with a gearbox to remove ash from the chamber under the burner in regular intervals two times a day for fie minute or on the basis of another setting in the deashing module, which is installed under the boiler hood. You can repeat the cycle any time by turning off and on the switch on the boiler. When the additional ash pan is completely full, the ash removal device (worm) will be automatically switched off and the deashing module will start to emit a sound signal. You can restart the device after cleaning (emptying) of the additional ash pan by merely turning off and on the switch on the boiler for 5 to 10 seconds.

Setting of deashing module AD01

CAUTION – ash removal device and ash pan for boiler D80P is not the same as in other DxxP boilers and it is sold on its own under a different code (the screw conveyor’s diameter is bigger). Capacity of ash pan enclosed with the ash removal device is 67 or 135 l. The module is situated under the casing of the boiler. Factory setting corresponds with the applied 15 W gearbox.

Automatic ash removal requires no particular handling; you only have to empty the additional ash pan regularly. The additional ash pan and its lid are attached and secured by two clips with a security clip, which have to be closed properly during operation of the boiler to avoid leakage of ash into boiler room. When installing this system follow the installation instructions supplied with it.

CAUTION – automatic ash removal is not designed for pellets with biological agents (hay, straw, grains etc.) as these form large and hard agglomerates, which can block the ash removal screw conveyor. In such cases the automatic ash removal should be replaced with a normal ash pan.