DESIGN

Askoll ENERGY SAVING is a wet rotor high efficiency circulator, driven by a permanent magnets synchronous motor (PM motor) controlled by an on board inverter. The motor is protected against overload thanks to a thermal protection and an automatic electronic release function of the rotor. No external protection is required. Operated by selector technology. LED user interface.

APPLICATION

Hot-water heating systems of all kinds, in domestic and commercial buildings.

PRODUCT FEATURES AND BENEFITS

• Very high degrees of efficiency due to Askoll permanent magnets motor

• Compact design: the smallest available on the market

• A LED provides information about the operation status of the circulator

• Electronic controls allow to set advanced features and load adjustment capacity Δp-c (constant differential pressure) and Δp-v (proportional differential pressure)

• Min-Max mode: allows to set the exact working point across the range

• The pump housing realized in composite plastic material is designed to work at high temperatures (TF95)

MOTOR TECHNICAL DATA

• Power supply: 1x230 V (-10%; + 6%); Frequency: 50 Hz

• Electrical connection: Pull resistant cable clamp PG11

• Energy Efficiency Index (EEI)*: ≤ 0,23 – Part 2

• Input power (P1): Min 3W, Max 56W

• Input current (I1): Min 0.03A, Max 0.44A

• Insulation class: H

• Protection class: IP44

• Appliance class: II

PUMP TECHNICAL DATA

• Ambient temperature: 0°C to +40°C

• Fluid temperature**: +2°C to +95°C

• Temperature range at max. ambient temperature:

of 30°C = +30°C to +95°C

of 35°C = +35°C to +90°C

of 40°C = +40°C to +70°C

• Max. operating pressure: Max 0.6 MPa - 6 bar

• Minimum pressure on the intake opening:

0.03 MPa (0.3 bar) at 50°C

0.10 MPa (1.0 bar) at 95°C

• Maximum relative humidity: ≤ 95%

• Sound pressure level: < 43 dB(A)

• Low Voltage directive (2006/95/CE): Standard used: EN 62233, EN 60335-1 and EN 60335-2-51

• EMC Directive (2004/108/CE): Standard used: EN 61000-3-2 and EN 61000-3-3, EN 55014-1 and EN 55014-2

• Ecodesign directive (2009/125/CE): Standard used: EN 16297-1 and EN 16297-2

* The benchmark for most efficient circulators is EEI ≤ 0,20

** To avoid condensation in the motor and the electronics the temperature of the pumped liquid must always be greater than the ambient temperature

PUMPED LIQUIDS

• Water for heating according to VDI 2035

• Mixtures of water and glycol with glycol percentages not greater than 30%

• Clean liquids, not aggressive and not explosive, not containing solid particles, fibers or mineral oils.

REGULATION AND CONTROL

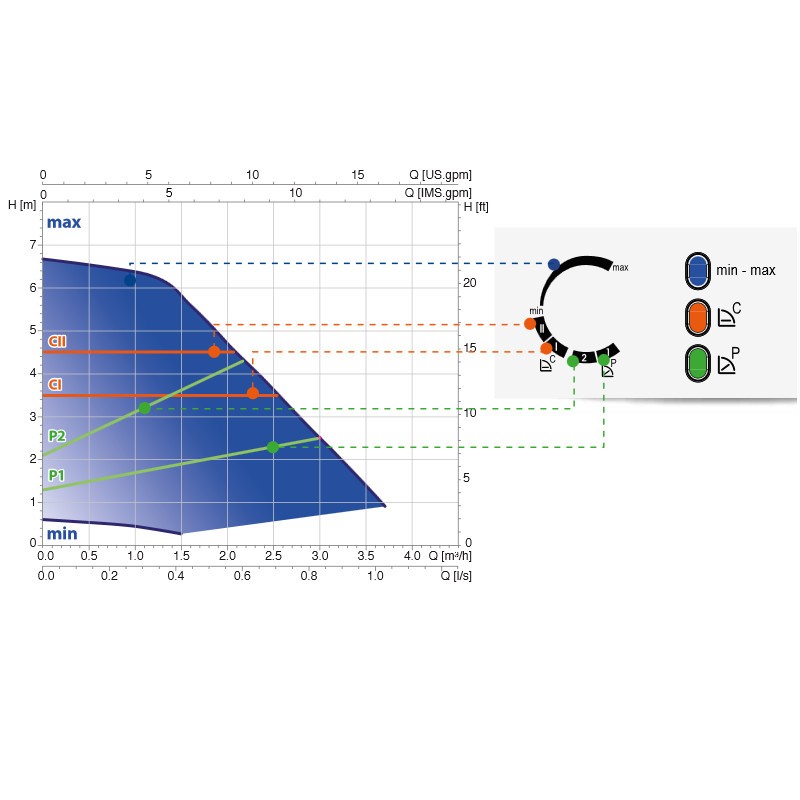

Turn the regulator to select the desired operating curve

• nr. 2 proportional-pressure curves (P1,P2)

• nr. 2 constant-pressure curves (CI, CII)

• min-max mode – Fixed speed

CERTIFICATIONS

• CE marking

• VDE GS marking

SCOPE OF DELIVERY

• Circulator

• Gaskets included

• Installation and operation instructions included