DC25SP is a new model 2018 with servo at the air intake. There also must be a special burner A25 for DCxxSP boilers code H0048. It also has servo for air controll.

For DCxxSP, CxxPS boilers is appropriate burner. ATMOS A25 (for models DCxxSP, CxxPS) 4,5 - 24 kW code: H0048.

INFO - DCxxSP and CxxSP boilers and burners in version Model 2018 are equipped with the function of automatic closing or opening of the air supply to the boiler/burner (using the actuator) when hearing with wood or pellets.

The boilers are equipped with an AGF2 flue gas sensor and a KTF20 boiler water temperature sensor for function of automati burner start after the wood burns out. Than the boilers are equipped with two KTF20 sensors (TV and TS) for controlling the burner with two temperatures on the accumulation tank. The whole set is sold in the maximum range, for fully automatic mode and simple plug and play installation.

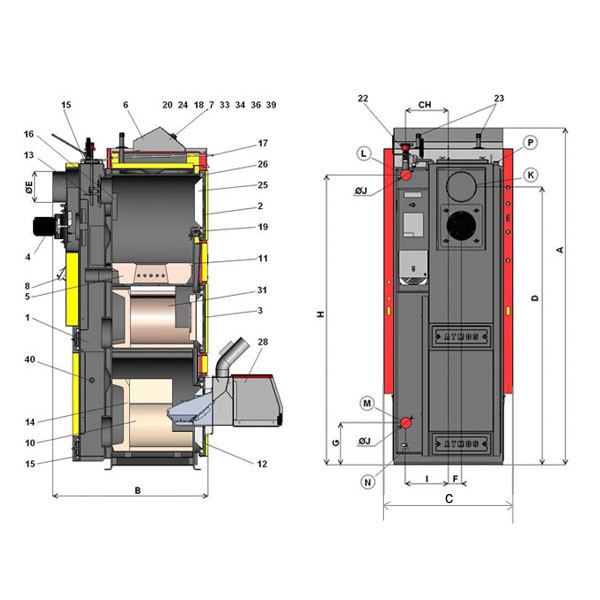

The boiler Atmos DC 32 SP proper is constructed as a body of three chambers situated one above another. The two upper chambers serve for the gasification of the wood, as you are familiar with from the classical gasification boilers that we produce as the standard. In the third, lowest chamber, is installed the required burner at the front, inlaid by ceramics to ensure the optimal quality of burning. Both the systems are separated by a water jacket so that they do not interfere with each other and, thanks to that, the boiler achieves high effectiveness when heating by the individual fuels. The combustion gases exhaustion is handled by one outlet and therefore only one flue is needed.

The operation of the Atmos boiler DC 32 SP is fully automatic to heat up water to required temperature with high efficiency and in a good quality of burning.

Fuel - wood barrelwood 12 - 20 % / heating capacity 15 - 18 MJ/kg diameter 70 - 150 mm

Fuel - pellets wooden pellets of quality, diameter 6 - 8 mm / white pellets

Wood boiler output 25 - 35 kW

Pellet boiler output 6 - 20 kW

Maximum length of wood 530 mm

Wood consumption during the season O 35 plnometry

Wood charging hopper volume 140 dm3

Weight of boiler 571 kg

Volume of water in boiler 160 l

Pellet burner type ATMOS, ERATO GP20 etc

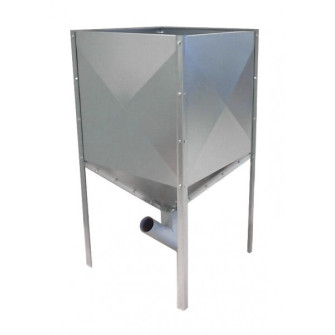

Pellets container EXTERNAL - 250, 500, 1000 l

Connecting voltage 230 / 50 V/Hz

Power demand at the start for pellets 1120 W

Power during the operation 120 W

Boiler class 4

Height: 1772 mm

Width: 678 mm

Depth with exhaust pipe: 957 mm

1. Boiler body

2. Charging door - wood

3. Ashpan door - wood

4. Gas exhaust ventilator (except for DC 15EP)

5. Heatproof pipe fitting - nozzle

6. Control panel 7 . Safety thermostat

8. Regulatory valve

9. Heatproof pipe fitting - extension of the ball space (Kombi)

10. Heatproof pipe fitting - ball space (Kombi)

11. Sealing - nozzles - 12 x 12

12. Door for the pellet burnery

13. Heating valve

14. Heatproof pipe fitting - back side of the ball space (Kombi)

15. Cleaning lid 16 . Screen

17. Heating valve rod

18. Thermometer

19. Burning space screen

20. Switch

21. Output regulator - Honeywell FR 124

23. Cooling loop

24. Regulatory thermostat

25. Door filling - Sibral

26. Door sealing

27. Ceramics - roof

28. Burner for pellets or extra LFOs

29. Heatproof pipe fitting - ball space (D 15)

30. Heatproof pipe fitting - inlay of the ball space (DC 15E)

31. Heatproof pipe fitting - ball space - wood

32. Heatproof pipe fitting - back side of the ball space - wood

33. Pump thermostat (only in DC 15EP)

34. Fuse (6,3 A)

35. Combustion gases thermostat (except for DC 15EPEP)

36. Switch

37. End switch with a button

39. Pump thermostat (DC 18-32 SP)P)

40. Measurement point for the combustion gases analyzer

ATMOS kombi boiler DC18SP, DC25SP, DC32SP (firewood + pellet) instruction manual