Pellet boiler Everclean 30 kW (PK0030)

Such combination and integration ensures perfect and efficient combustion of pellets and helps to save heating costs.

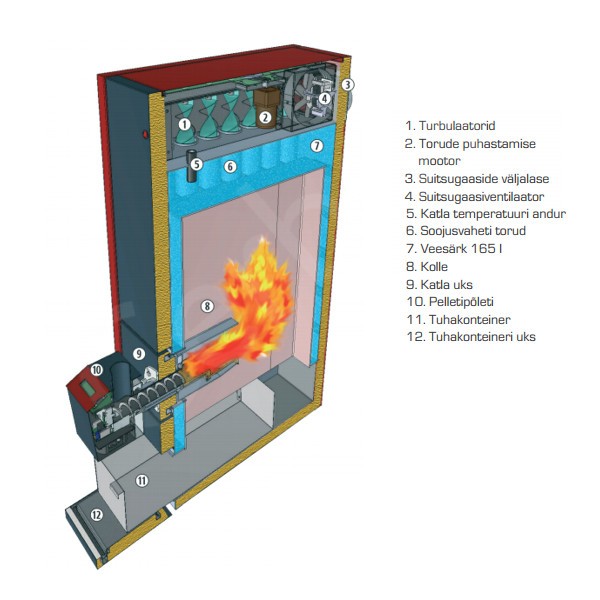

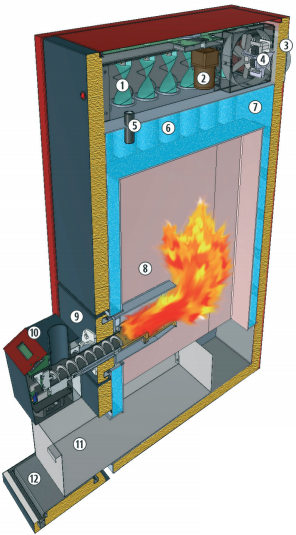

Boiler Everclean has self-cleaning system that enables simple and periodical cleaning of heat exchangers tubes. Burner’s controller controls frequency of cleaning cycles according to parameters set up. Self- cleaning system delivers collected ash to capacious ash box of boiler.

For filling, emptying and connecting with heating system the boiler has 2 connection fittings with 1’’ internal thread on back side of boiler and 2 connection fittings with 1’’ external thread on up side of boiler in distance 125mm. The flue gas fan that adjusts boiler’s draft is integrated to boilers outgoing smoke tube. The direction of fan smoke tube outlet is possible to change from horizontal to vertical by using intermediate flange. Burner’s controller controls the speed of flue gas fan according to under-pressure in burners burning chamber or selected power level.

Pellet boiler Everclean has temperature and pressure gauges.

Safety devices that the boiler includes:

- safety valve (overpressure relief valve)

- door switch

- safety thermostat

Safety valve applies when pressure in boiler exceeds 2,5 bar.

Door switch does not enable to start burner when boiler’s door is open. If boiler door will be opened during burning status, the door switch interrupts burners work and burner goes to end burning state. By closing the door burner continues normal burning cycle.

Safety thermostat interrupts boilers work when its temperature rises over 95°C. Safety thermostat has to be reset manually.

Pellet boiler Everclean 30kW

Pellet boiler Everclean 30kW

Boiler class according to EN 303-5: 5

Efficiency: 95%

Rated thermal output: 30 kW

Minimal thermal output: 10 kW

Boiler water volume: 100 l

Boiler’s weight w.o water net/bruto: 196/205 kg

Recommended heating water temp: 75°C

Minimal temp. of returning water: 55°C

Highest working temperature: 90°C

Applying temperature of safety thermostat: 95°C

Furnace draft: 2-6 Pa

Flue gas temperature at rated output: 150-180°C

Flue gas temperature at partial load: 100-120°C

Max. operating pressure: 2,5 bar

Test pressure: 4 bar

Appr. fuel consumption at rated output: 4 kg

Appr. fuel consumption at minimal output: 2 kg

Dimensions W x D x H: 600x600x1510 mm

Width without side panels (in-take width): 500 mm

Supply main: 230V, 50Hz

Earthing: TN-S

Power consumption: 25-40 W

Power at igniting: 500 W

Power at standby: 3W

Protection class: IP20

Capacity of expansion tank: Depending on heating system litres

Need of combustion air in rated output: >60 m3/h

Optimal size of combustion air inlet hatch: 200 cm2

Volume of ash box: 38 l

Flange hole diameter: 90 mm

Diameter of fuel feeder tube: 60 mm

Number of turbulators: 4 pc

Flue gas tube connection: 112 Ø mm

Chimney minimal diameter: 100 mm

Combustion chambers length: 404 mm

Connection fittings 2 on back side and 2 upside: 1"

Pocket for thermostat on upside of boiler: 1/2"