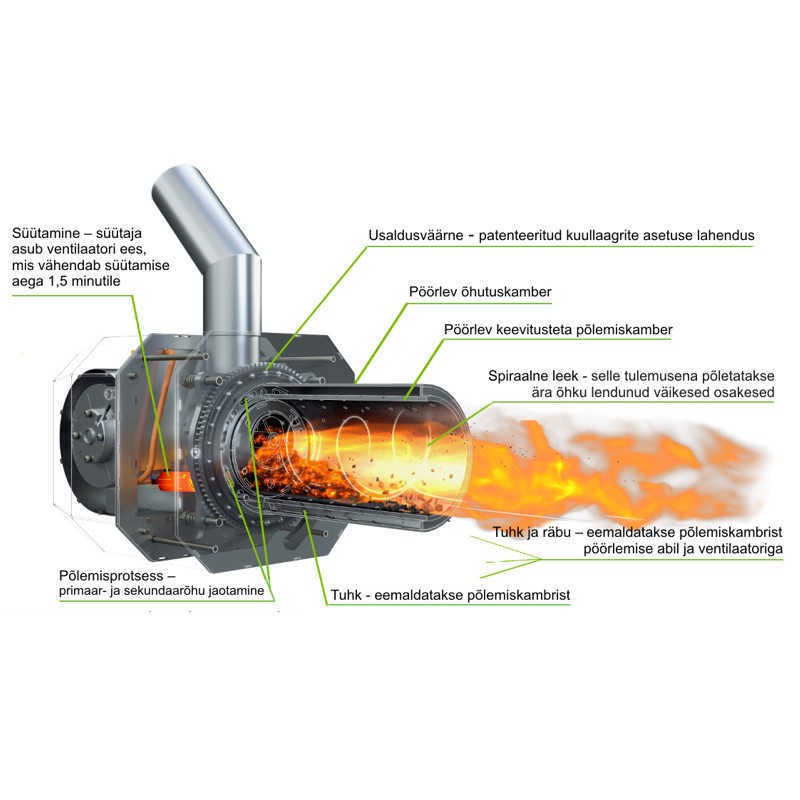

Rotation of a combustion chamber prevents adhesion of slag to the chamber formed during combustion. The slag moves forward and exits the combustion chamber due to cyclic rotation. Moreover, no adhesion facilitates the cleaning process of the burner and significantly affects its service life. Combusted bed is oxygenated over the entire length of the combustion chamber, and further mixed by the rotating combustion chamber that enhances the combustion process and allows complete combustion of the supplied fuel.

The pellet burner KIPI ROT-POWER is designed to work with central heating boilers for solid fuels, as well as several models of gas or oil boilers with a combustion chamber enabling the collection and selection of ash.

The pellet burner KIPI ROT-POWER is an ecological device as it uses fuel from renewable sources. It also features a small demand for electricity.

The pellet burner KIPI ROT-POWER is equipped with a controller which is responsible for an optimal dosing of fuel in accordance with the parameters set by the user, and variable speed power control. This controller operates with a room thermostat which helps to maintain the temperature in the room.The burner's controller is also equipped with temperature sensors of the boiler and DHW. The controller can be connected to circuit pumps of central heating and DHW.

KIPI pellet burner user manual

Declaration of conformity (ENG)