Ecological wood gasification boilers Generator Dokogen boilers are characterized with a special chamber which is on both sides laid with special ceramic shaped parts, with primary air inlets in the lower section and with ceramic nozzle and in lower chamber with spherical ceramic parts. Rear flue duct is equipped with a tubular heat exchanger.

Gasification of wood (inverse burning) with subsequent combustion of wood gas in ceramic combustion chamber ensures optimum burning of all combustible components. The air supply and combustion process are controlled with exhaust fan. This allows quick ignition and good combustion of the boiler since the firing up. The flame temperature is 1000 - 1250 °C.

Inverse burning (gasification) and ceramic combustion chamber enable practically complete combustion with a minimum of harmful exhalations. The boilers meet limits of European regulations for environmental friendly product and belong to 5th class of boiler standard ČSN EN 303-5. Meet the most demanding requirements of the EU - ECODESIGN 2015/1189.

Advantages of wood gasification boiler Atmos DC 50 GD

- Option to burn large pieces of wood

- Large fuel container - long time of burning

- Tube heat exchanger

- High efficiency over 90 % - primary and secondary air is preheated to a high temperature

- Ecological burning - boiler class 5 - ČSN EN 303-5, ECODESIGN 2015/1189

- Exhaust fan - ash cleaning without dust, boiler room without smoke

- Cooling loop protecting against overheating – without risk of boiler damage

- Exhaust fan automatically switches off when the fuel burns out – exhaust (flue gas) thermostat

- Pohodlné vybírání popela – large space for ash (when burning wood you have to clean it once per week)

- Small size and low weight

- High quality

Boiler Atmos DC 50 GD technical data

Boiler output: 49 kW

Specified chimney draught: 24 Pa

Height: 1435 mm

Width: 680 mm

Depth: 1120 mm

Boiler weight: 565 kg

Boiler water volume: 128 l

Fuel chamber volume: 170 dm3

Maximum wood length: 530 mm

Boiler efficiency: 92 %

Flue gas temperature at nominal output: 183 °C

Specified fuel: Dry wood with heating capacity 15 - 17 MJ.kg1, water content at least 12 % - max. 20 %, average 80 - 150 mm

Min. return water temperature: 65 °C

Boiler class: 5

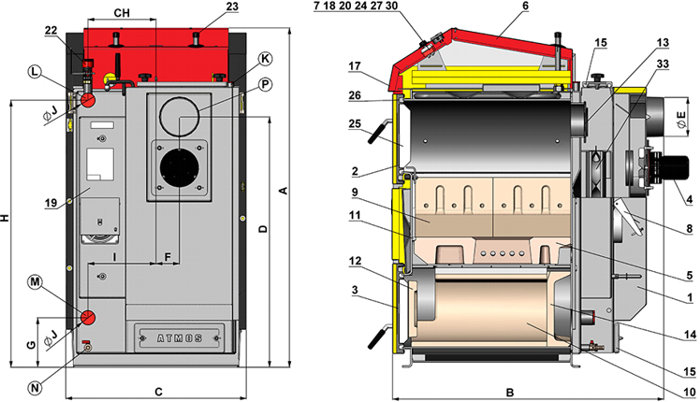

Boiler Atmos DC 50 GD drawings key:

| 1. Boiler body 2. Filling door (upper) 3. Ash-pan door (lower) 4. Exhaust fan (S) 5. Heatproof shaped piece - nozzle 6. Control panel 7. Safety thermostat 8. Regulating flap 9. Heat proof shaped piece – for type GD - combustion area side 10. Heat proof shaped piece – for type GD - spherical space 11. Sealing – nozzle - 12 x 12 (14 x 14) 12. Heatproof shaped piece – half moon 13. Ignition valve 14. Heat proof shaped piece – for type GD - rear face of spherical space |

15. Cleaning lid 17. Ignition valve pulling rod 18. Thermometer 19. Intake duct - air duct 20. Main switch 22. Draught regulator - Honeywell FR 124 23. Cooling loop protecting against overheating 24. Ventilator control thermostat (boiler) 25. Door filling - Sibral 26. Door sealing – cord 18 x 18 27. Flue gas thermostat 30. Capacitor of exhaust fan 33. Flue gas brake (Turbulator) |

Boiler Atmos DC 50 GD dimensions:

A - 1435 mm

B - 1120 mm

C - 680 mm

D - 1095 mm

E - 150/152 mm

F - 78 mm

G - 185 mm

H - 1152 mm

CH - 256 mm

I - 256 mm

J - 2"

Regulation of the Atmos GD boilers

Electrical - mechanical - output of the boiler is controlled with a regulating air flap operated with the draught regulator, FR 124 type, which automatically opens or closes the safety valve according to a set output temperature of water (80 - 90°C). When setting the power regulator, much attention should be paid because the regulator has another important function other than power regulation - it also secures the boiler against overheating. A controlling thermostat located on the boiler panel regulates the exhaust fan according to a set temperature (80 - 85°C). A temperature lower by 5°C should be set on the controlling thermostat rather than on the FR 124 draught regulator.

Boilers are also equipped with the waste gas thermostat which serves to switch off the exhaust fan after the wood burns out.

The boiler runs at a reduced output even without a fan - heating is not lost when the electric power fails. At up to 70 % of its rated output, the boiler can be operated without a ventilator.